Fire Test On A Standing Georgian Dwelling Bath (UK) 1967

With the need to provide more units of accommodation, many large multi-storey houses previously occupied by one family were being converted into separate dwellings. In most cases, it was impossible to comply with the degree of fire resistance required by the Building Regulations, or the provision of non-combustible elements of structure. It therefore follows that applications for relaxation or dispensation of the Building Regulations were sought in the majority of cases

Report on a Fire Test of a Ceiling in a Georgian Dwelling House on 2 March 1967, published in the Cost C17 Final Report vol 2 (pages 73-80)

Note that many of the technical testing methods described in this report will now have been superceded.

At the time of the test (1967), no amendements to the English Building Regulations Part E had been made. The Regulations referred to are those current at that time.

Reason For Test

With the need to provide more units of accommodation, many large multi-storey houses previously occupied by one family were being converted into separate dwellings. In most cases, it was impossible to comply with the degree of fire resistance required by the Building Regulations, or the provision of non-combustible elements of structure. It therefore follows that applications for relaxation or dispensation of the Building Regulations were sought in the majority of cases.

In a building of three or four storeys which was to be converted into flats or maisonettes, if alternative means of escape could be achieved at parapet or roof level, and the main means of escape was protected by walls and doors having half hour fire resistance, it was considered that the provisions of Building Reulgations E5, E9 (7), E10 and E12 were unreasonable for the following reasons

• A ceiling consisting of at least 1 inch thick plaster on laths, with square-edged flooring over joists 2 inches thick, will provide half hour fire resistance, which is a reasonable time for vacating the rooms of a building in case of fire

• The British Standard 476 Fire tests on building materials sets out conditions which are far more severe than those actually experienced in a room of a dwelling when a fire occurs

• Compliance with the Regulations would not be possible, economically or structurally, in this type of building

In order to test this theory, it was necessary to simulate the behaviour of a typical domestic fire, from the time of ignition, through the build-up period, for at least 30 minutes and then having extinguished the fire, to examine the condition of the ceiling and the floor above, and having established that the theory is correct, to use such information to support future applications for relaxation of the Building Regulations where similar conditions occur.

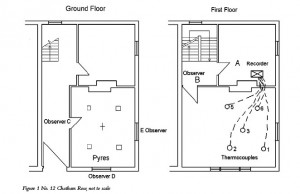

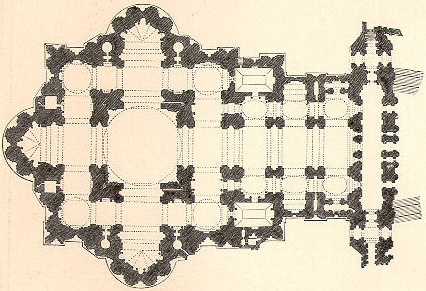

The house chosen was No.12 Chatham Row and was an end-of-terrace house, built about 1760 and comprising a basement, with an open area at the front, to one side and to the rear, and three additional storeys. The external walls were of 5 inch thick Bath ashlar stone. The interiors of the rooms were lined with timber panelling to a height of 3 feet above floor level and plastered above.

The wall separating the ground floor room (the one under test) and the entrance passage was constructed of lath and plaster on a timber studding.

• The floors were seven inch by one inch square edged flooring on eight inch by two inch joists

• The ceilings were constructed of one inch plaster on laths with ornate cornices

• The roof of timber trusses and rafters with slate covering

• The house on plan measured twenty seven feet by eighteen feet, while the room (the ceiling of which was under test) measured twelve feet, five inches by thirteen feet and was nine feet high

Measures Taken Prior To The Test

A visit was made to the Fire Research Station at Boreham Wood to ensure that the test would be similar to tests carried out by the Joint Fire Research Organisation (JFRO), and the preparations were made strictly in accordance with the advice given at that visit.

Firstly, the room was brought up to the standard one would expect to achieve after conversion, except for decoration, and this entailed the following work

• Reglazing the windows and replacement of sash cords to enable the windows to operate normally

• Testing the key between the ceiling plaster and the laths, and infilling cracks in the plaster

• Replacing floorboards in the room over the test room

• Re-floating a concrete hearth in the room over the test room

• Covering the partition wall between the test room and ground floor passage with quarter inch insulation board and plasterboard to ensure half hour fire resistance

• Infilling the door panels and covering the whole internal surface of the door with quarter inch insulation board to give half hour fire resistance and increasing the door stops to a thickness of one inch

In addition, it was necessary to provide a suitable fire load, and the JFRO indicated that it was desirable to have a fire load of five to six pounds per square foot of floor area. Better results would be obtained if this was provided by cribs of rough cut timber rather than by articles of furniture.

Four cribs were prepared. Each crib weighed 216.67lbs. which gave a fire load of 5.67 lbs. per sq. ft. of floor area. In addition to this imposed fire load, each wall had the original panelling to a height of 3 inches above the floor level.

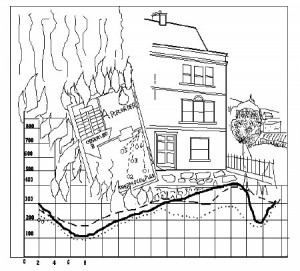

The floor covering was removed from the floor of the room over the test room with the exception of a narrow strip of standard hard board covering a crack between two floor boards. It was essential that the temperatures during the test were accurately recorded and accordingly five thermocouples were installed in the ceiling of the test room to record the temperatures at a position 3 inches below the ceiling at intervals over the area of the ceiling.

Arrangements on the Day of the Test

Recording instruments, to which the thermocouples were connected, were installed in the first floor rear room. The floor of the test room was covered all over with 1” of damp sand and at the points where the cribs were to stand, sheets of insulation board were placed on the sand. These measures were to ensure that the fire would not burn downwards and affect the floor structure. Four cribs were set up in the test room in the positions shown on the plan.

The ignition pyre was built at a central point between the four cribs and trails led away to the cribs. The pyre and trails were of wood shavings, wood chips and sawdust and was 1’ 6” high and the trails 6” high. Immediately prior

to the ignition of the pyre three pints of paraffin were poured on the pyre to simulate similar conditions to that of an overturned oil heater. The Fire Brigade Officer assumed responsibility for fire control during the test and also provided observers to record conditions during the test.

Recording Equipment

The test required that the temperature at five points, 3 inches below the ceiling, of the test room, should be measured at short intervals from the time of ignition of the fuel, affording the fire load, in that room. Thermocouples were used and the wire selected was nickel-chromium/nickel aluminium T1/T2.

Duration Of Test

In order to simulate as near as possible the conditions and development of a normal fire in a dwelling, it was decided to allow the fire to burn 45 minutes from the time of ignition. The reasons for this period being chosen are as follows

• In a normal domestic fire with oxygen supply limited to that found in a room with doors and windows closed, severe smoke logging occurs at an early stage and the fire could be self-extinguished through lack of oxygen. Under these conditions the ceiling of the test room would not be given a satisfactory test as maximum temperatures would not be reached. Therefore, a flow of air to the fire had to be guaranteed in order to ensure it would continue to burn. Accordingly, a 2 ½” gap was left above the top sash window from the beginning of the experiment and at zero + 3 minutes a gap of 3” was opened at the bottom of the lower sash window. This was at zero + 9 minutes, increased to 6”. During the whole of the experiment the normal flue from the grate of the room was providing a cross draught.

• As the structure of the ceiling was to be tested for a period of at least 30 minutes under normal conditions appertaining at a domestic fire, and at the end of the first 15 minutes approximately, of such a fire, it is usual for a ‘fall off ’ of temperature to occur until the fire is ventilated in some way, e.g. breaking of glass in a window, it was decided that the 30 minute period of test for the ceiling should take place after that initial 15 minutes period has passed. This meant that from the time of ignition of the pyre, to the time of completion of the experiment, a 45 minute period was indicated.

• Although, in some circumstances it would have been desirable to allow the fire to burn until the ceiling under test had collapsed, in this instance it was necessary to submit the ceiling to the heat from a normal domestic fire for a period of at least 30 minutes and then, if the ceiling still remained intact, to extinguish the fire and carry out a close examination of the fire damage done to the materials forming the construction of the ceiling and the floor above.

• The door and the partition wall, between the Test Room and the passageway from the staircase to open air, had been modified to conform with normal half hour fire resisting standards. A 30 minute fire test was, therefore, demanded and again the extra 15 minutes initial burning period, appeared to be indicated in order that the performance of the door and partition could be measured against that of the ceiling.

Weather Conditions

The day was dry with cloudy and bright periods. There was a slightly westerly wind. The front window of the room under test, faced west.

Summary Of Test

Zero: At 1205 hours the incendiary materials forming the ignition pyre and comprising wood chips, wood shavings and sawdust over which 3 pints of paraffin had been poured were ignited. When reference is made to this time in the following report it will be as ‘zero’.

Zero + 2½: Within the first 2½ minutes the pyres and trails were burning well, with some build up of heat and then smoke became quite dense as oxygen in the air within the room was rapidly reduced.

Zero + 5: At zero plus 5 minutes some temperature reduction showed on the thermocouple readings and a very slight percolation of smoke occurred at the top of the half hour fire resisting door, into the passage. The window at this point of the room was opened 3” at the bottom in addition to the 2½” at the top, in order to encourage air circulation. The cribs were now alight at the bottom. Quite heavy smoke logging of the room was apparent but the cribs were still visible.

Zero + 7½: In the next 1/2 minutes (zero 5 – 7½) the top pane of the front window cracked in two places and all cribs were alight at the inner corners with smoke issuing from the tops. Temperatures started to take an upward curve.

Zero + 10: Temperatures continued to rise and a slight increase of smoke penetration was noticed around the top of the half hour fire-resisting door. The front window was opened another 3” at the bottom ( 6” in all) and flames were noted coming from the tops of the cribs at all inner corners. Vision across the room improved.

Zero +12½: Continued rise in temperature. First signs of smoke on first floor – very slight percolation between the fireplace and the door, at base of wall. Cribs now burning well on inner surfaces. Side window glazing very hot.

Zero + 15: Temperatures still rising. Highest recorded at No. 3 thermocouple 3270 C. Smoke percolation at 1/2 hour fire resisting door very slight. Small increase in temperature of door panels. Lower pane of front window cracked. Cribs burning well with flames 2’ 6” high from inner surfaces. Good vision most of room but ceiling obscured by smoke.

Zero + 17½: One thermocouple showed slight decrease in temperature recorded (No. 5) others a slight increase.The Yale lock on the half hour fire resisting door, hot but bearable to touch. Slight percolation of smoke around the door jamb. Molten paint dripping from framework of front window and top pane cracked in the side window.

Zero + 20: Slight decrease in temperature readings of thermocouples 1 and 3. Increases on all others.Yale lock too hot to touch. Smoke becoming dense inside room and flames less visible, but cribs showing increased burning.

Zero + 22½: Increase all round in temperature recordings of thermocouples. Increase in smoke percolation around door stops and door jambs. Cribs well alight nearest door. Increased number of cracks in front top window. Severe discolouration of side window by smoke.

Zero + 25: Temperature reading of centre thermocouple (No. 3) same as zero + 22½ . Slight decrease in reading from

No. 5. All others slightly up. First signs of smoke through cracks between floorboards at a point immediately above the partition wall between the test room and the passage. Slight smoke also showing in corner of room at side of the door. Again over the passageway. No apparent increase in temperature of the half hour fire-resisting door frame but slight increase evident on panels. Fire in cribs sluggish. Sash cords to lower half of front window burnt through and window dropped. Glass only slightly broken away and a reduction of visible flame with a corresponding increase of smoke evident.

Zero + 27½: Considerable drop in temperature readings of thermocouples 1, 2, 3, & 4. Slight drop in case of No. 5. Smoke now coming through crack at end of another floorboard over the ground floor passage and some percolation of smoke into the Recording Room, first floor, rear. No smoke coming from around the door stops and jambs. Pegs removed from below top section of front window to simulate sash cords burning through. Window dropped and glass dislodged where cracks had already been apparent. Smoke seen to be issuing from cracks in walls and lintel over the side window.

Zero + 30: Sudden rise in temperature recording of all thermocouples other than No. 5. Smoke now increased from the base of both door jambs near landing at first floor level and also issuing in centre of room near the thermocouple (No. 3). Very slight smoke percolation around the half hour fire-resisting door. Flames in the room high and licking the ceiling. Slight flaking from ceiling, possibly distemper or similar decorative material. Bottom pane of glass in side window cracked.

Zero + 32½: Steady increase in temperature recordings of No. 1-4 thermocouples. Slight decrease in temperature recorded at No. 5. Smoke convected from window of room on fire below, through the unglazed first floor window. Signs of smoke from the top of the wooden wainscoting near front window. Paint softening on the top rail of the half hour fire-resisting door and smoke issuing under pressure from the Yale lock. Smoke also apparent from between the top of the door and the door stops. Cribs well alight and tops of window frames and frame around window opening burning.

Zero + 35: General rise in temperature recordings. In the case of No. 2, 3, 4, 5 from 800 C – 1050 C, and No. 1 a very slight increase of 60 C. At first floor front room level considerable smoke percolation was apparent from around the sill of the front window. Smoke also percolating between the skirtings and the floorboards all along the wall between the front room and the centre of the room. The paint on the panels of the half hour fire-resisting door started to blister. The top pane of glass in the side window blown outwards by excessive pressures in the test room.

Zero + 37½: Rapid rise in temperature recorded. In the case of thermocouple No. 5 – 2260. Following a crash of glass breaking (side window – see Zero + 35) the smoke and heat entering by the first floor front window became less. Some smoke started to come up the staircase. A greater quantity of smoke apparent through the Yale lock on the half hour fire-resisting door and smoke around the door increased.

Zero + 40: Continued rapid rise in temperature recordings. 3200C in the case of thermocouple No. 1. Smoke percolation continued at first floor front room level and fire observed for the first time at the side of the front window. Heat through the unglazed windows, rising from the room below became intense. A slight increase of smoke noticeable from the upper area of the door around the stops. Fire in ground floor room at peak with plenty of ventilation by way of the two windows which were now without glazing. Slight flaking of ceiling is still all that is apparent. No breaking down of separation.

Zero + 42½ : Highest temperature reached No. 3 thermocouple, 10000 C. All others, 8950 C. or above. Fire still at its peak. Half hour fire door shows slight burning at the top. Upper panels still comparatively cool. The ceiling of the room was intensely white and appeared to be glowing. No signs of failure.

Zero + 45: Temperature still between 8430 C and 9870 C. The latter being the measurement at No. 3, thermocouple. Most smoke percolation at the first floor front room was between the chimney breast and the door. Smoke percolation also quite heavy around the base of the wainscoting panelling on the wall between No. 12 and No. 11 Chatham Row. Inspection afterwards showed that this smoke had entered the hollow partition wall around the door at ground floor level and had then risen into the void between the ceiling and floor above which was situated over the passage. The room was now becoming smoke logged. The half hour fire-resisting door was starting to warp at the top allowing smoke to pass more freely. The whole of the ceiling still apparently sound. None of the stopped in cracks had broken down. Cornices still in position. Fire still extremely hot but showing signs of being past its peak.

Zero + 45½: Temperature reading No. 1 thermocouple -7650 C, a fall of 1750 C. Ceiling still apparently sound.

Extinguishing

Zero + 46: Extinguishing of the fire commenced using 1” hose reel jet. This was augmented by 1/2 “ jet. Steam produced, caused rapid cooling of the surface of the ceiling, and the first cracks appeared. These seemed to be in positions where original cracks had been repaired. Approximately 8 sq. ft. of ceiling then fell away and access of air to the ceiling void and exposed laths resulted in some of the laths, already conditioned by conducted heat, catching on fire. Extinguishment was carried out without undue disturbance of tested material, but water hitting the door surface caused the asbestos fibre board surface to split and curl. This same effect was produced where water hit panels of asbestos fibreboard which had been fitted over recesses which were suspected of not being up to half hour fire-resisting standards. The plasterboard covering the partition wall was damaged considerably during extinguishing because fire had entered the hollow partition and water had to be directed through into the hollows at various points causing spalling of the plasterboard and plaster of the partition itself.

Observations during the test.

The ceiling under test registered the passage of flame for the whole of the test period of 45 minutes. There was no sign of cracking, distortion or material breakdown during the whole of the test other than a brief period, in the early stages, when some initial flaking occurred on some parts of the surface of the ceiling eg distemper. The fire had reached its peak at zero + 42½ and then the temperature curve had started to descend. At the peak period it was noted that the fuel cribs in the test room were almost exhausted having burned down to within 6” of the floor. It is, therefore, reasonable to assume that a continual drop in recorded temperature could have been expected had the fire been allowed to burn after zero + 46. The treatment of the inner surface of the door and partition, between the ground floor passage and the Test room, to afford half hour fire-resistance was completely successful in spite of the fact that the plasterboard additional covering had not been skimmed with plaster to seal the joints. The penetration of the fire which did occur into the hollows of the laths and plaster partition over the door, was not through the protected surface but by way of the architrave over and to the side of the door opening. The fire thus by-passed the protection. Even so this must have occurred at the very late stages of the test as no flame was noticed on the floor above until extinguishing the fire in the test room well under way. It was then necessary to remove some of the lath and plaster surface of the partition in order to extinguish the hot spot.

At no time during the whole of the test was the escape route from upper floors so affected by smoke or heat that it could not be used. The separation afforded by the half hour fire-resisting partition wall and door was adequate for the whole 45 minute period of the test. Although some smoke percolation occurred past the ends of floorboards in the front room at first floor level, no flame penetrated at any time through that area of the floor over the test room. Considerable pressures were applied by hot gases both to the ceiling and the walls. This was most evident at zero + 32½ when smoke issued in the form of a horizontal jet from the Yale lock on the door, and at zero + 40 when the glass of the upper sash window at the side of the test room blew out with considerable force. The fire followed the usual pattern which can be expected when a fire occurs in a room in domestic property in which there is a normal fire load, the fire has some ventilation and is not disturbed for some period by opening doors or breaking windows. In the case of this test there was an early rise in temperature, brought about by the paraffin soaked pyre burning fiercely and then as the cribs became involved and oxygen in the atmosphere of the room became rare, a sluggish period followed. This occurred during the first ten minutes after which, by increasing the flow of air over the window sill of the front window, more rapid combustion took place. A gradual rise in temperature for a further 15 minutes when again some smoke logging developed and temperatures dropped. This was at the time that sash cords burnt through, which were holding up the bottom section of the front window. When the top window section was dropped the new supply of air stimulated the fire and a general very rapid rise in temperature resulted culminating in the peak of 10000C. being reached at zero + 41½. Fuel was at this time becoming exhausted and in the next 2 minutes a decline in temperature commenced. The heat of the test fire was sufficient to cause almost all of the 11/4” plaster skimming on the inside of the front wall of the room to leave the stonework.

Observations after the Test

The ceiling under test withstood the application of heat from a normal fire load underneath for the whole of the 45 minute test period without any visible signs of deterioration. No cracks were apparent, and after the initial flaking of surface decorative materials no further spalling or flaking was noted. The plaster cornice around the room also remained intact, other than in one short section immediately above the front window where it cracked and dropped slightly.

When water was applied to the fire in the remains of the cribs, the steam created caused, after approximately halfminute, sudden contraction of the ceiling and cracks opened up at points where previously cracks had been undercut and sealed with plaster during the preparation period. A few moments later approximately 8 sq. ft. of ceiling plaster fell to the floor. It was noticed that although some of the laths had carbonised due to heat conducted through the plaster they were not on fire, but as soon as they were exposed small flames appeared on the carbonised surfaces. These had to be extinguished to prevent further damage and during the extinguishing, further collapses of ceiling plaster took place.

With greater exposure of the underside of the floor and the joists it was most apparent that the floorboards were undamaged and the lower edge of only some of the joists, although charred in places, the charring was not of sufficient depth to measure with any accuracy. A considerable portion of the laths still remained undamaged.

A composition gas pipe passing through the void between the floor and the ceiling was undamaged. In addition, an accumulation of small twigs and fibrous material, possibly collected by mice and in itself readily combustible, found in a void between floor joists, resting immediately on top of the laths supporting the plaster ceiling, was not damaged in any way by fire or heat. The plaster decorative cornice around the room was intact after the fire on three sides of the room. In the case of the fourth side, it was only the section immediately above the front window that some signs of damage occurred. At this point the cornice cracked vertically and a section approximately 18” long dropped slightly but did not become dislodged.

Although during the whole of the 45 minutes covered by the test, some smoke did percolate into the passage and also into the first floor room above the test room, at no time was the movement of people prevented along the passage, up the staircase or around the rooms.

The fire, during the period of the test, did not penetrate the ceiling and floor structure to the room above. At zero + 58, after extinguishing had commenced, a small flame was noticed at a crack between floorboards which had been covered with a strip of standard hardboard. The hardboard was burning and flame started to travel rapidly over its surface. When the source of the flame was investigated it was found that the fire from the test room had penetrated the architrave of the door at a point over the top of the half hour fire-resisting door, and had then by-passed the ceiling of the test room by travelling up the hollow of the partition wall. This was also the route by which most smoke percolation occurred into the first floor room.

The partition and door which were converted to half hour fire-resisting standards stood up to the test remarkably well. Some percolation of smoke and heat by-passed the test ceiling by way of the hollow partition. This, however, would possibly not have occurred, had the partition been skimmed with plaster and cracks filled in accordance with normal procedure.

The door reacted extremely well. It was only at zero + 45 that the door began to warp and allow smoke to escape in increasing volume. When the remains of the asbestos fibreboard cladding was removed from the inner face of the door including the panel infills, some of the original green paint was still intact under the infills.

Conclusions

The fire resistance of a normal ceiling in a middle class Georgian house is such that it is capable of preventing fire from spreading to the floor above for at least a 30 minute period. It is normal for vertical separation between rooms and exit routes to afford half hour fire-resistance. To be consistent, therefore, a ceiling between such rooms and rooms above should also be half hour fire-resisting and a fire resistance of one hour plus, as required in some circumstances by the building Regulations 1965, between floors, would appear to be excessive. It would appear that the tests applied under furnace conditions to ceiling and partitions, to assess fire resistance, is too stringent and does not simulate conditions as they really occur in a fire in a building. Under the circumstances it would appear that the fire resistance of a sound Georgian ceiling does not require to be upgraded to one hour. Such an upgrading could result in the fire below the ceiling breaking out horizontally into the exit route and preventing escape by that route, before any warning of a fire is transmitted to persons living above.